Stone crusher plant make use of a large range of equipment, such as intake hopper vibrating feeder or pre-screener, crushing unit (such as jaw crushers, impact crusher, heavy type hammer crusher, and cone crusher etc), vibrating screen, loading belt conveyor and other needed machines(dust suppression system, sprinkler system, dust remover machine etc)

Configuration of stone crusher plant According to rock characters, the normal configuration of stone crusher plant is as below

1.Medium and Soft rock and stone:

GZD series vibrating feeder + PE series jaw crusher + PF Impact crusher + YK series circular vibrating screen + several belt conveyor

2.Medium and hard rock and stone:

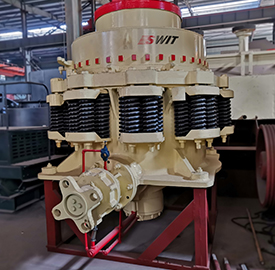

GZD series vibrating feeder + PE series jaw crusher + PYB / CS / HPC cone crusher + YK series circular vibrating screen + several belt conveyor;

Working process of Working process of stone crusher plant 1.Raw materials are evenly conveyed into jaw stone crusher for primary crushing via the hopper of vibrating feeder.

2.The crushed stone materials are conveyed to crushing plant by belt conveyor for secondary crushing before they are sent to vibrating screen to be separated.

3.After separating, qualified materials will be taken away as final products, while unqualified materials will be carried back to the stone crushing equipment for recrushing.

4.Customer can classify final products according to different size ranges. All the final products are up to the related standards within and beyond China. Dust is generated during the working process while the dust control units are needed.

crushing plant is mainly composed with vibrating feeder, jaw crusher, cone crusher / impact crusher, vibrating screen, belt conveyor and electrical controlling system. Capacity can be 30-1000t/h. For different requirements on finished products sizes also can equip with cone crusher.

Email: vip@switmac.com

Email: vip@switmac.com Tel: +86-18737119558

Tel: +86-18737119558