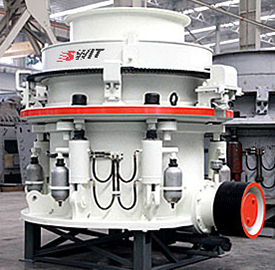

iron ore, granite, limestone, quartzite, sandstone, cobblestone and etc.

Hydraulic cone crusher is applied to cement mill, mining, building construction, road & bridge construction, railway construction and metallurgy and some other industries. Materials like iron ore, granite, limestone, quartzite, sandstone, cobblestone and some others are easily crushed by cone crusher.

Email: vip@switmac.com

Email: vip@switmac.com Tel: +86-18737119558

Tel: +86-18737119558